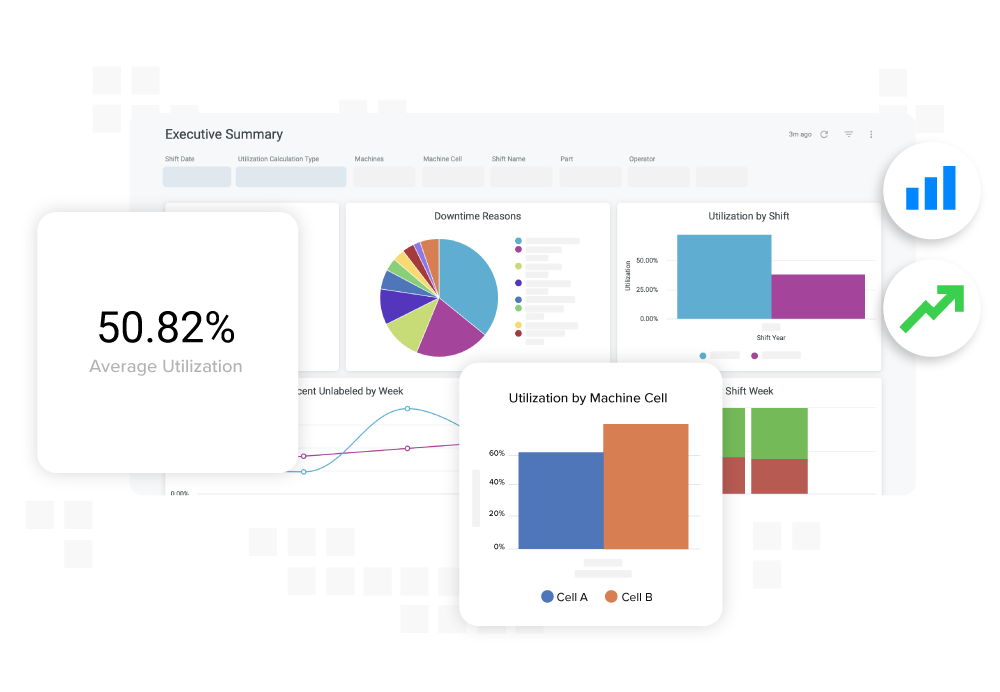

We Are Six Sigma (WASS) is an official partner of Amper Technologies. Amper helps you identify production bottlenecks and maximize capacity. Their suite of manufacturing applications comes with a unique machine monitoring solution that reads the electrical current of a machine to determine the machine state. Those electrical signals are then turned into real-time data and insights.

The team at WASS has used Amper in many deployments with great success. It stands out to us among other machine monitoring solutions due to:

- ● The ease of installation and how quickly you can get the solution up and running (15 minutes/machine)

- ● The ability to work on old or brand-new machinery

- ● The adaptability of the system to your processes

WASS can set up Amper on 2 machines in your facility with our demo units—free for 30 days. From there we can discuss how the system can be deployed at a larger level, and how WASS can help you in your Lean Six Sigma journey using the data.

How it works

No PLC upgrades. No IT integration. No interruption.

- 1. Install non-invasive sensors to your machines’ power supply. Connect to cellular or Wi-Fi Gateway and allow for system calibration.

- 2. Access real-time usable machine data from anywhere on any device.

Never question what’s happening on your shop-floor again

Visual management boards can be set up to monitor your shop in real-time.

Enable operators with help resources

Use tablets for gathering downtime and part count data, as well as andon communication for operators to call for help when issues arise.

Deploy a maintenance schedule based on true utilization hours

Plan preventative maintenance more accurately with usage-based maintenance schedules. Request maintenance tasks and keep real-time logs.

Escalate issues with alerts

- Notify team members when a critical piece of equipment is down with email & text alerts. Escalate alerts to upper management if the problem persists after a fixed time period.